Distributor: Product Supply (Form Board)

Committed to sustainable foaming technology

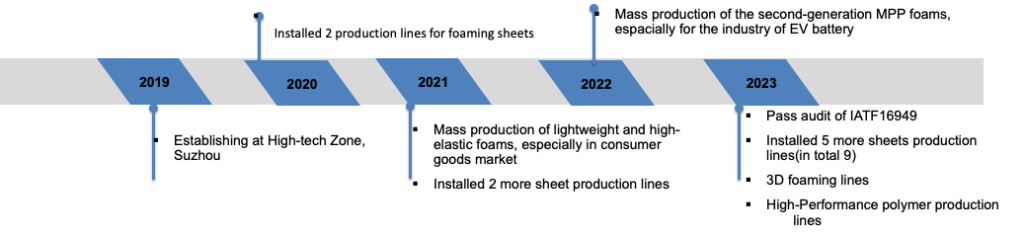

Overview & Milestones

Established in March 2019, focusing on the development of high-performance & light-weight polymer foaming technology.

Up to now, 150 employees, over 20,000 square meters facilities, 60 million RMB of actual capital utilized; 9 polymer microcellular foam production lines with capacity of 2500 sheets/day (by May-2023).

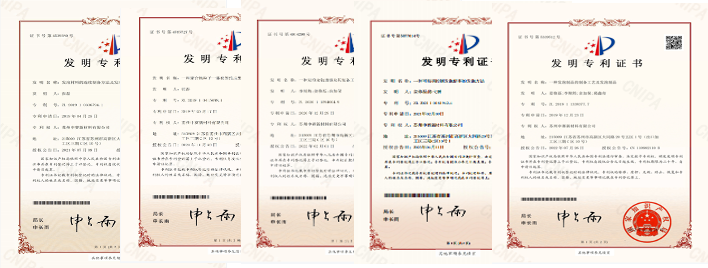

Core equipment and key foaming technology are independently developed with own IP. 12 invention patents ; R&D center & analysis and testing center.

Unique advantage – IP (Process & Equipment)

•Various Patents(more than 20 patents), including PCT patent, applied across the foaming process, machinery and tooling.

•FTO (Freedom To Operate) assessment obtained from the law firm without infringement, against the patent existed in the key regions globally.

Quality Management System

Biz-Division

Consumer Products:Industrial Products:Special Foam

(High-Performance

Technical route map

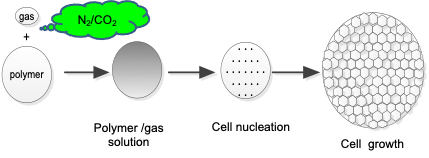

Physical foaming mechanism

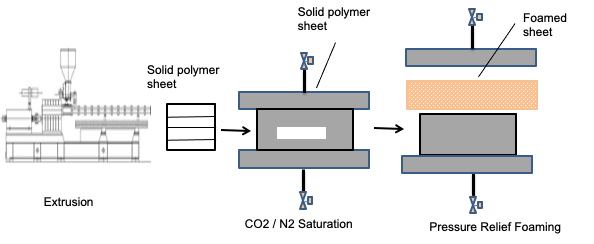

Sheets foaming process

Technical Route Map

Utilize clean supercritical microcellular foaming technology to realize the lightweight of high-performance elastomers, general-purpose polymers and special polymers.

Endowing foams with excellent mechanical, thermal, electromagnetic, acoustic and optical properties, Zhongchu has foams of plates, beads, block foaming, foam rolls and so on.

The thermoplastic non-crosslinked products route covers all consumer products and general industrial products, in order to ensure the recyclability and recycling of materials.

Cross-linked foams are only available for products with demanding and complex application requirements.

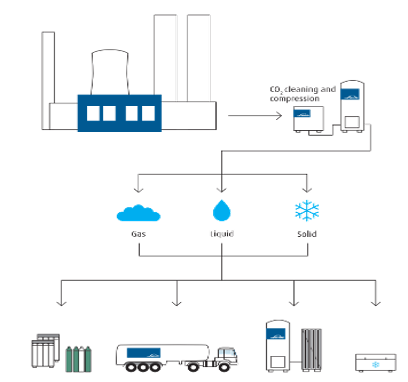

Carbon footprints – CO2 (N2)

•CO2 is captured, cleaned and compressed from waste products of chemicals production by Linde AG

•No extra CO2 is produced in Zhongchu foaming process .

Autoclave facility

Manufacturing process – Foam Sheets

Manufacturing process – 3D block midsole

Raw material

Injection molding

Solid 3D block

High Pressure Autoclave

Midsole

No accessory ingredient or chemical foaming agent in whole process

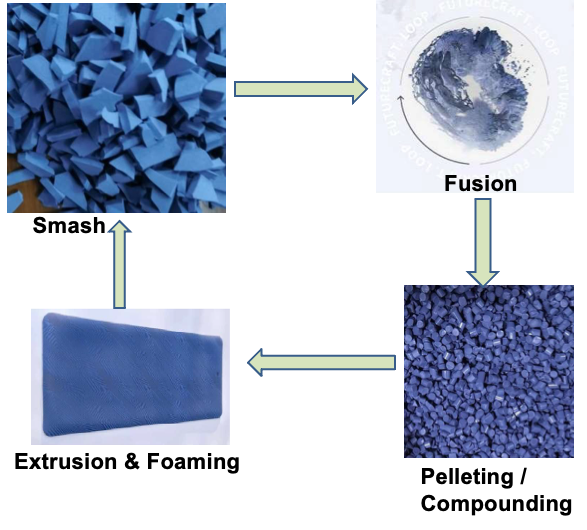

Recyclability

Applications

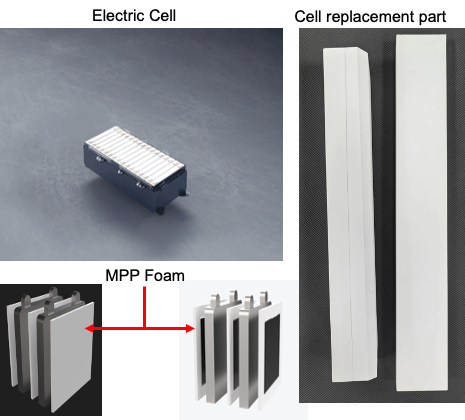

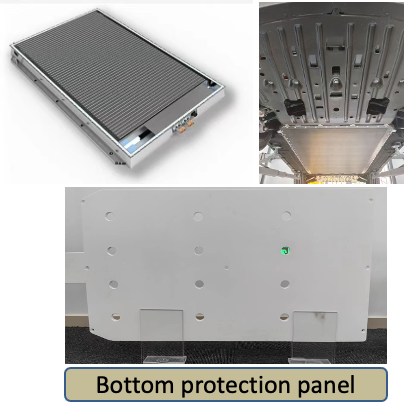

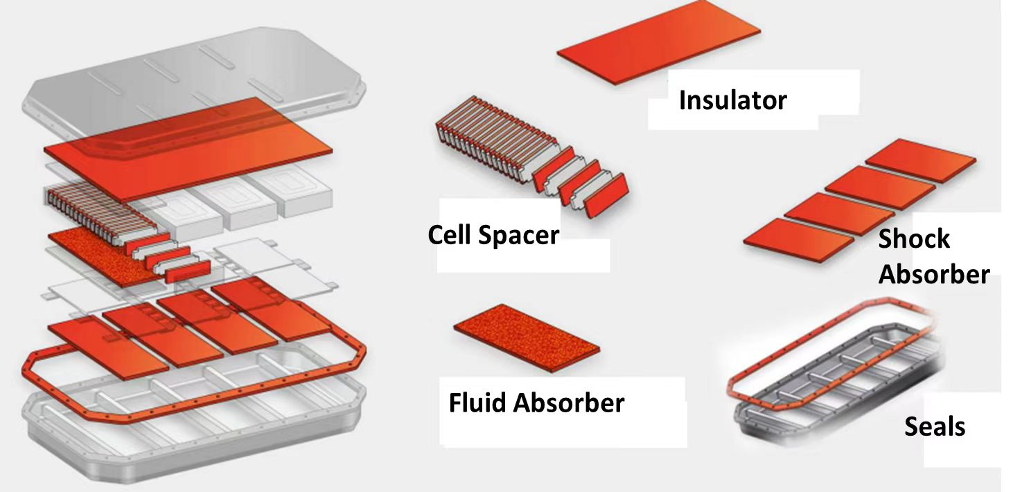

Industrial Products – EV Battery

Battery Application

Consumer Products

Typical Foaming Polymers

M-TPU

Aliphatic TPU (A-TPU)

M-TPEE

M-PEBAX(Bio-Based)

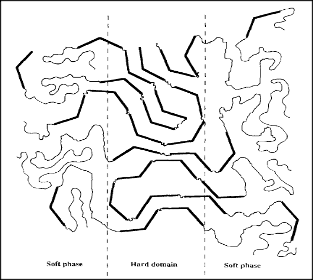

The micro-structural phase separation of hard segment and soft segment contributed to the high performance

Hard segment (HS) domains diffuse in a soft segment (SS) matrix.

Value-added Solution

Physical & Supercritical foaming

High energy return, lightweight and long-lasting cushioning.

No smell, no additional chemicals, foamed by N2/CO2.

No crosslinking enables recyclability

Bio-based version is also available, Content up to 44%

Low temperature resistant

| MATERIAL | Raw Material Supplier | Tg Value |

| PEBAX(Bio-Base) | Arkema | -35.8℃ |

| TPU | BASF / HUNTSMAN | -49℃ |

| TPEE | DUPONT | -50℃ |

Typical Product – M-Pebax Sheet

| 检验项目 Test Item | 测试方法 Test Method | 单位 Unit | M-PEBAX07 |

| 密度 Density | ISO 845:2006 | g/cm3 | 0.07±0.02 |

| 硬度 Hardness | SATRA TM 205-16 | Shore C | 35±4C |

| 拉伸 Tensile Strength | ISO 1798:2008 | MPa | 2 |

| 伸长率 Elongation at Break | ISO 1798:2008 | % | 150 |

| 撕裂强度(裤型) Method A Tear (Trouser Test) | ISO 8067:2008 | N/cm | 15 |

| 撕裂强度(直角) Method B Tear (Angle Test) | ISO 8067:2008 | N/cm | 60 |

| 落球回弹 Ball Resilience | ASTM D3574 | % | 80 |

| 压缩形变 Compression Set | ASTM D395 | % | 38 |

Typical Product – Aliphatic TPU(A-TPU) Sheet

| 检验项目 Test Item | 测试方法 Test Method | 单位 Unit | Aliphatic TPU |

| 密度 Density | ISO 845:2006 | g/cm3 | 0.07±0.02 |

| 硬度 Hardness | SATRA TM 205-16 | Shore C | 30±5C |

| 拉伸 Tensile Strength | ISO 1798:2008 | MPa | 2.27 |

| 伸长率 Elongation at Break | ISO 1798:2008 | % | 163.92 |

| 撕裂强度(裤型) Method A Tear Trouser Test | ISO 8067:2008 | N/cm | 18.27 |

| 撕裂强度(直角) Method B Tear Angle Test | ISO 8067:2008 | N/cm | 69.6 |

| 落球回弹 Ball Resilience | ASTM D3574 | % | 80 |

| 压缩形变 Compression Set | ASTM D395 | % | 24 |

Consumer products

Footwear

Sports

High Performance Foam

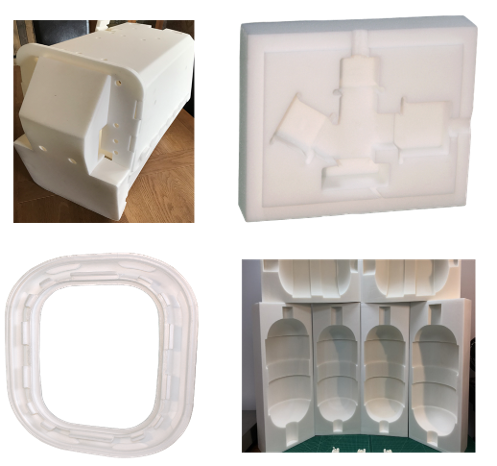

Insulation and Seals

Applications

•Insulation Tubes

•Window Surrounds/Seals

•Equipment Packaging

Benefits

•Flammability

•Lightweight

•Heat Insulation

Low Coefficient of Thermal conductivity – Less material needed-

•Fabrication Simplification

Engineered fixing method removes glue

High Performance Foam

Insulation and Seals

Applications

•Insulation Tubes

•Window Surrounds/Seals

•Equipment Packaging

Benefits

•Flammability

•Lightweight

•Heat Insulation

Low Coefficient of Thermal conductivity – Less material needed-

•Fabrication Simplification

Engineered fixing method removes glue

Customers & Partners